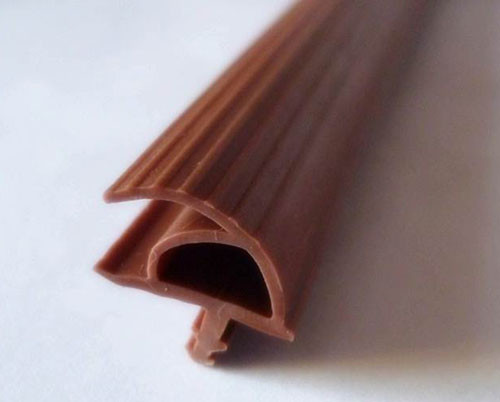

EPDM door and window sealant strip

The rubber strip on doors and windows usually has three seals from the outside to the inside, and the seals at the outermost and innermost are mostly partially broken. Therefore, the truly complete seal is one seal, which is the large sealing strip in the middle. EPDM sealing strips can be made in the form of foam co extrusion. The large rubber strip in the middle, which plays a key sealing role in doors and windows, is generally made in the form of foam co extrusion to ensure the compression and overlap of the seal, further enhancing the sealing effect.

The quality of sealing strips is tested by professional laboratories, and we do not have the conditions to conduct inspections, but there are simple methods for comparison. Judging from the appearance of the rubber strip, there are no obvious flaws. Smell the rubber strip, EPDM rubber strip has a special odor, but not pungent. Generally, chemicals have their own odor. If the rubber strip has a pungent odor, it may be a low-quality product. Weighing comparison shows that for the same length, a lighter rubber strip is better because the rubber strip is mainly composed of raw materials and various additives, and those with high raw material content are lighter. The combustion method involves distinguishing between the flame and the powder left behind during the combustion of EPDM, which requires some professional knowledge and will not be described in detail.